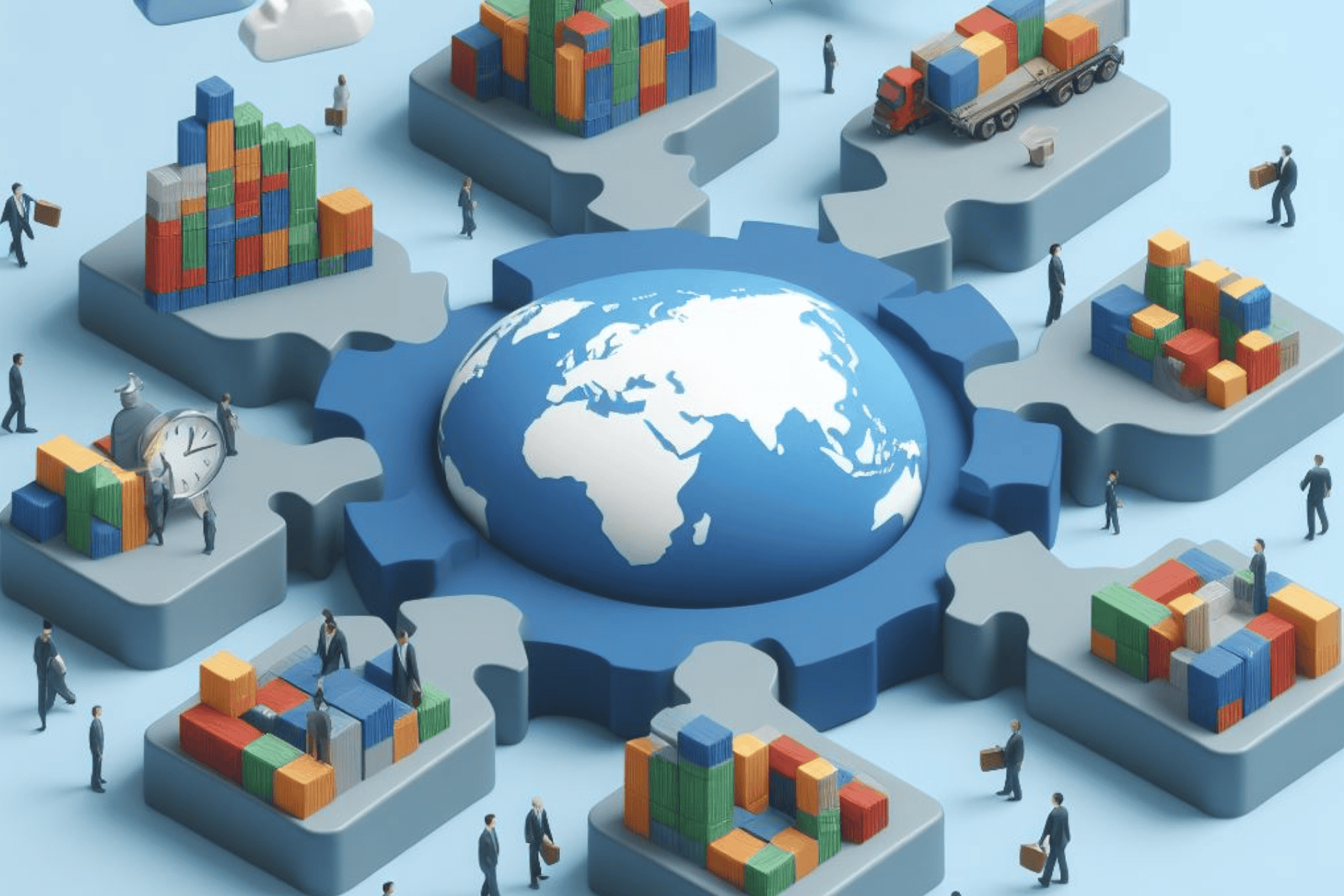

Building a resilient supply chain is paramount for export businesses seeking long-term success in the global marketplace. By embracing diversification, technology, collaboration, and proactive risk management, businesses can withstand disruptions and capitalize on opportunities, ensuring sustainable growth and profitability.

In today's global marketplace, export businesses face a myriad of challenges, from geopolitical tensions to natural disasters and pandemics. These uncertainties underscore the critical importance of developing a resilient supply chain. A resilient supply chain not only ensures the smooth flow of goods but also safeguards against disruptions, enabling businesses to thrive even in the face of adversity.

Understanding the Importance of Resilience

The term "resilient supply chain" refers to a supply chain's ability to withstand and recover from disruptions while maintaining its core functionality. For export businesses, this entails having contingency plans in place to mitigate risks at every stage of the supply chain, from sourcing raw materials to delivering finished products to international markets.

Key Strategies for Building Resilience

- Diversification of Suppliers: Relying on a single source for raw materials or components leaves businesses vulnerable to disruptions. By diversifying suppliers across different regions, export businesses can reduce dependency on any one supplier and mitigate the impact of unforeseen events.

- Investing in Technology: Embracing technology such as data analytics, artificial intelligence, and blockchain can enhance supply chain visibility and traceability. Real-time data analytics enable businesses to identify potential disruptions early on and respond swiftly, minimizing the impact on operations.

- Collaborative Partnerships: Building strong relationships with suppliers, logistics providers, and other stakeholders fosters collaboration and information sharing. In times of crisis, these partnerships can prove invaluable, enabling businesses to access alternative resources and find creative solutions to challenges.

- Inventory Optimization: Maintaining excessive inventory ties up capital and increases storage costs, yet insufficient inventory can lead to stockouts during disruptions. Export businesses must strike the right balance by adopting inventory optimization strategies that consider demand variability and lead times.

- Risk Assessment and Scenario Planning: Conducting thorough risk assessments and scenario planning exercises allows businesses to anticipate potential disruptions and develop contingency plans accordingly. By simulating various scenarios, businesses can identify vulnerabilities and devise strategies to mitigate risks proactively.

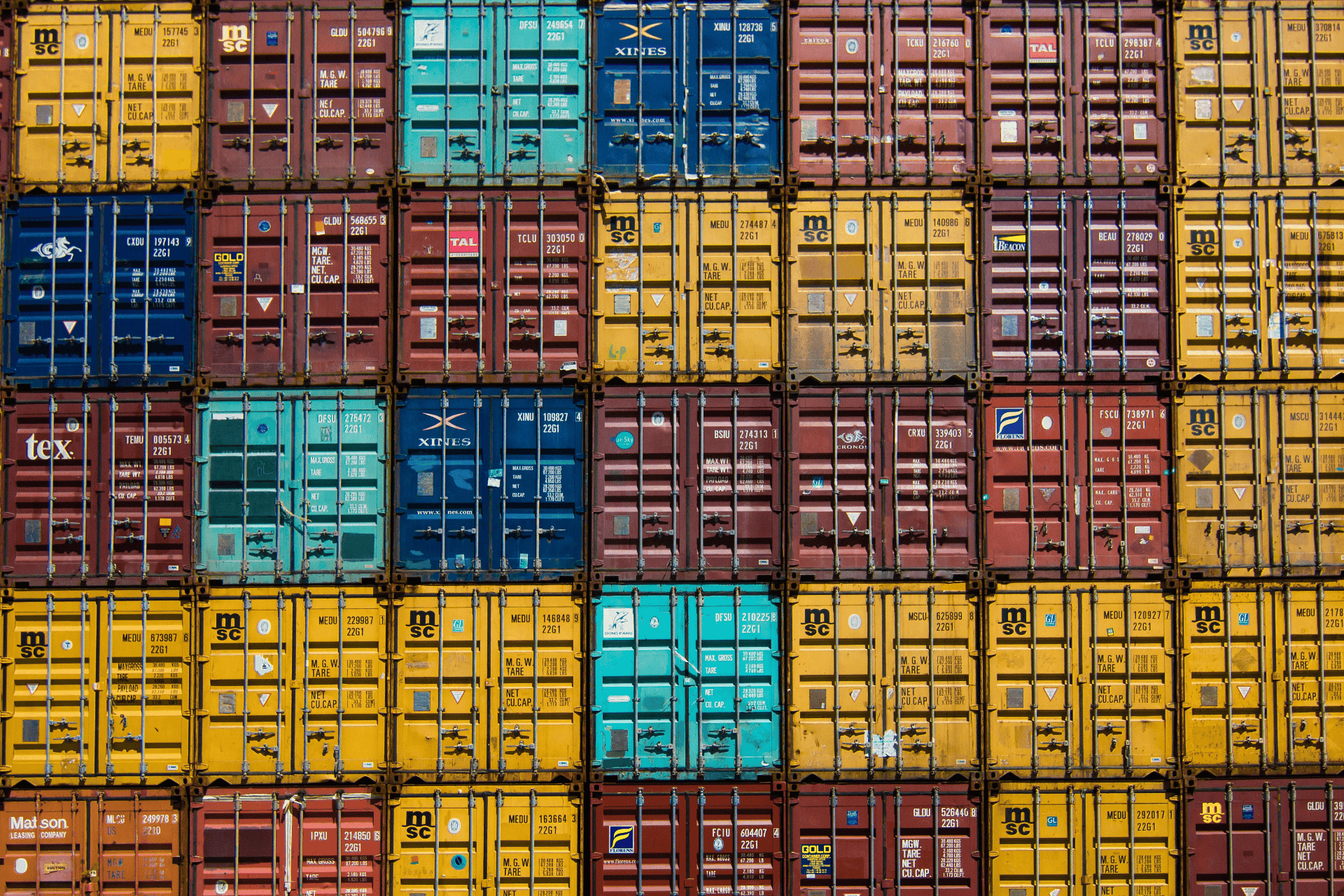

Case Study: Lessons Learned from COVID-19

The COVID-19 pandemic wreaked havoc on supply chains worldwide, exposing vulnerabilities and disrupting global trade. However, businesses that had invested in resilience fared better than their counterparts. For instance, companies that had diversified their supplier base were better equipped to navigate lockdowns and factory closures in different regions.

Looking Ahead: Future Trends and Challenges

As export businesses continue to expand their global footprint, they must stay attuned to emerging trends and challenges. Geopolitical tensions, climate change, and evolving consumer preferences are just some of the factors shaping the future of supply chain resilience. By staying agile and adaptive, businesses can future-proof their supply chains and thrive in an ever-changing landscape.

ExportBusiness #SupplyChainResilience #GlobalTrade #RiskManagement #BusinessStrategy #SupplyChainManagement #Logistics #COVID19Response #BusinessContinuity #ResiliencePlanning

Related Information