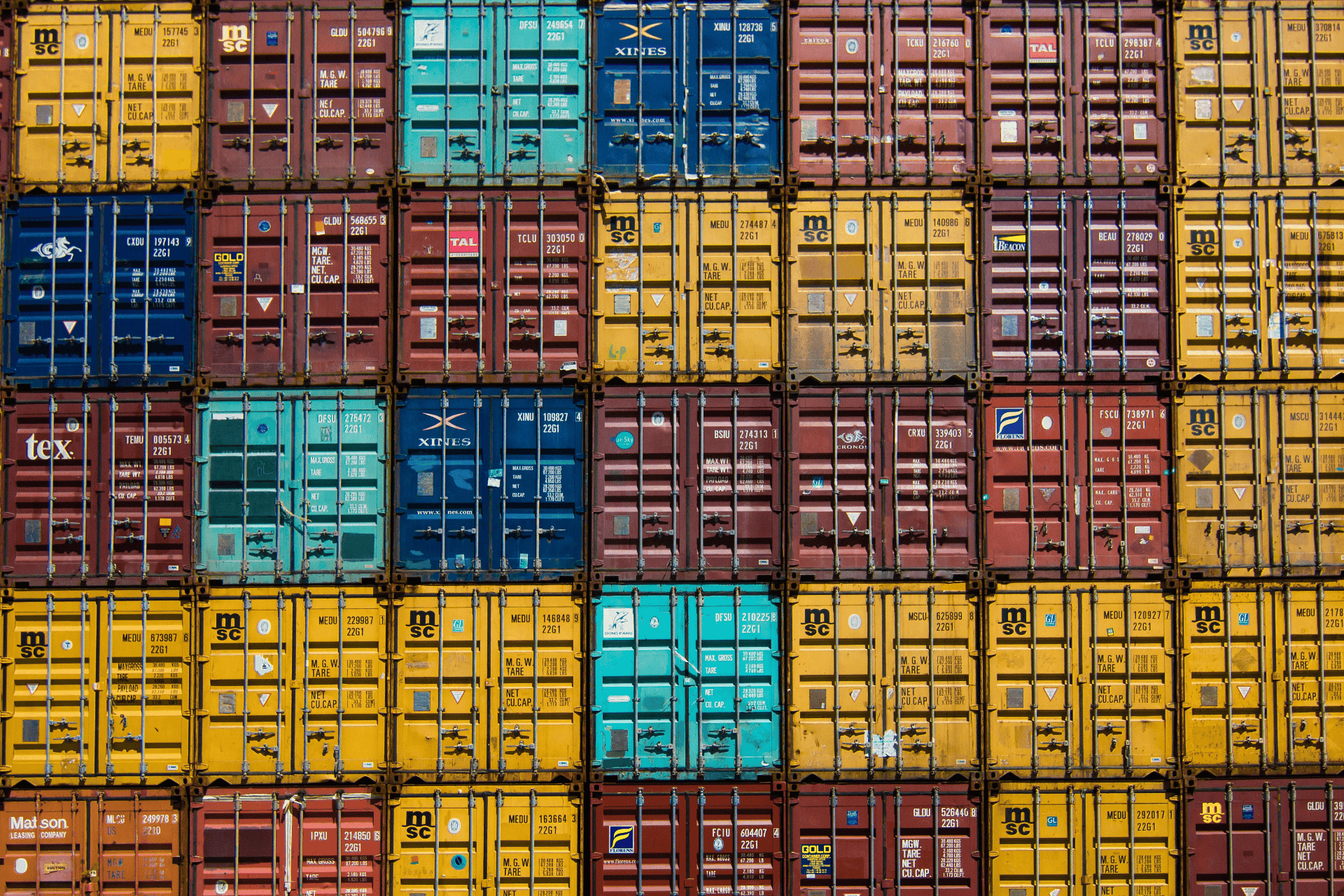

In the ever-expanding global marketplace, the significance of efficient export packaging cannot be overstated. As businesses strive to reach new markets and satisfy diverse consumer demands, the need for robust packaging solutions that ensure product integrity during transit becomes paramount. Fortunately, the landscape of export packaging is witnessing a transformative wave of emerging technologies, promising enhanced protection and efficiency like never before.

One of the most noteworthy advancements in export packaging is the utilization of smart materials and coatings. These innovative materials possess dynamic properties that adapt to environmental conditions, ensuring optimal protection against factors such as humidity, temperature fluctuations, and mechanical stress. For instance, self-healing coatings can automatically repair minor damages, maintaining the integrity of the packaging throughout the journey.

Furthermore, the integration of IoT (Internet of Things) technology has revolutionized the tracking and monitoring capabilities of export packaging. Smart sensors embedded within packages provide real-time data regarding location, temperature, humidity levels, and even potential shocks or impacts. This enables businesses to proactively address any issues that may arise during transit, minimizing the risk of damage and ensuring timely delivery of goods.

Another emerging trend in export packaging is the adoption of sustainable materials and practices. With growing environmental consciousness among consumers and regulatory pressures to reduce carbon footprints, eco-friendly packaging solutions are gaining traction. Biodegradable materials, recyclable packaging, and innovative designs aimed at minimizing material usage are becoming increasingly prevalent, aligning with the principles of sustainability while still providing adequate protection for shipped goods.

Moreover, advancements in 3D printing technology are reshaping the landscape of export packaging customization. With the ability to rapidly prototype and produce intricate designs, 3D printing offers unparalleled flexibility in creating tailored packaging solutions optimized for specific products. This not only enhances protection but also allows for greater branding opportunities and differentiation in the market.

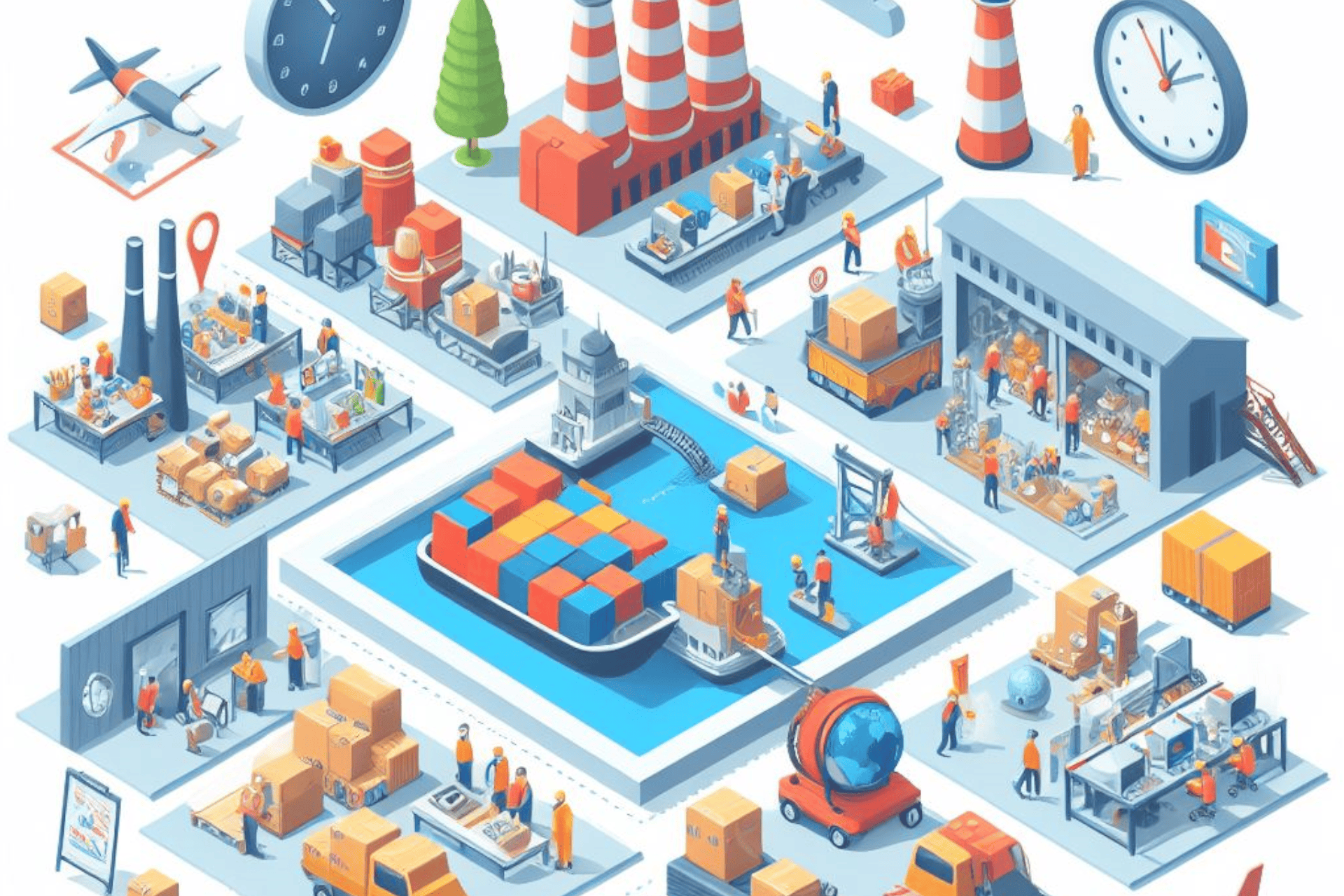

In addition to materials and technology, automation is playing a pivotal role in streamlining the export packaging process. Automated packaging systems equipped with robotics and artificial intelligence can efficiently handle tasks such as packing, labeling, and palletizing, reducing human error and increasing throughput. This not only enhances the speed and reliability of packaging operations but also minimizes labor costs and resource wastage.

#ExportPackaging #SmartMaterials #IoT #SustainablePackaging #3DPrinting #Automation #GlobalTrade #Innovation #Technology #Sustainability

Related Information