Achieving equilibrium between cost, quality, and risk within global manufacturing footprints is a multifaceted endeavor that demands strategic foresight, meticulous planning, and agile execution. By prioritizing strategic site selection, fostering collaboration and partnerships, embracing technology integration, and committing to continuous evaluation and adaptation, businesses can navigate the complexities of global manufacturing with confidence, resilience, and success.

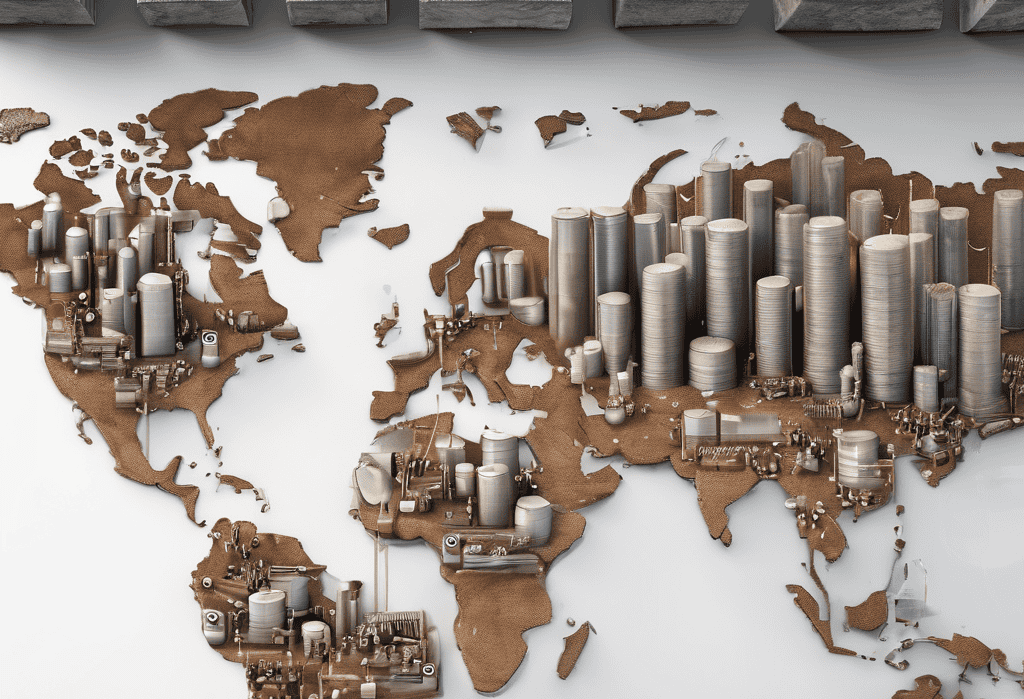

In the intricate world of manufacturing, the quest for the perfect balance between cost-effectiveness, quality assurance, and risk management has never been more critical. As businesses expand their global footprint to capitalize on diverse markets and optimize production efficiency, they must navigate a complex web of factors to ensure success. Here, we explore the art of harmonizing cost, quality, and risk within global manufacturing footprints.

The Dynamics of Global Manufacturing Footprints

Cost Considerations:

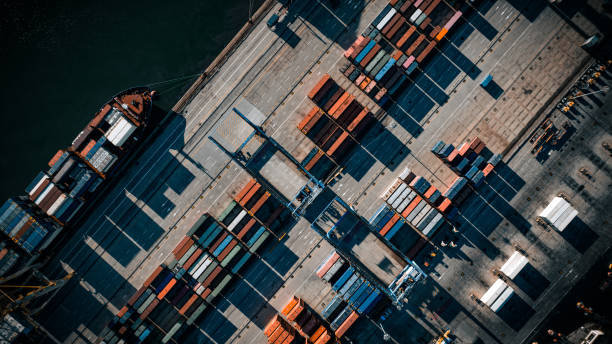

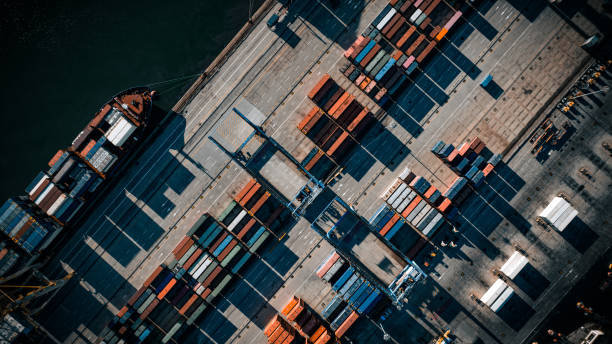

Cost optimization is often a primary driver behind establishing a global manufacturing footprint. By leveraging economies of scale, accessing lower labor costs, and capitalizing on tax incentives, businesses can reduce production expenses significantly. However, it's essential to consider not only direct production costs but also factors like transportation, tariffs, and currency fluctuations that can impact overall expenses.

Quality Imperatives:

Maintaining consistent product quality across diverse geographical locations is a cornerstone of successful global manufacturing. Quality standards must be upheld to meet customer expectations, regulatory requirements, and brand reputation. This necessitates robust quality control measures, standardized processes, supplier audits, and ongoing training to ensure adherence to quality benchmarks throughout the supply chain.

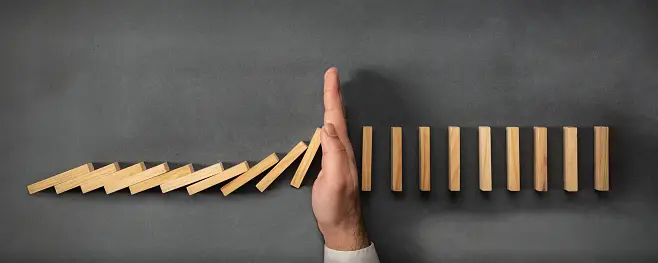

Risk Mitigation Strategies:

Global manufacturing introduces a myriad of risks, ranging from geopolitical instability and supply chain disruptions to regulatory compliance issues and intellectual property theft. Effective risk management entails identifying potential threats, implementing contingency plans, diversifying suppliers, and establishing clear communication channels to mitigate and respond to unforeseen challenges promptly.

Strategies for Achieving Balance

Strategic Site Selection:

Careful consideration of site selection is paramount in optimizing cost, quality, and risk within a global manufacturing footprint. Analyze factors such as labor availability, infrastructure, proximity to raw materials and markets, political stability, and regulatory environment to identify optimal locations that align with business objectives and mitigate risks effectively.

Collaboration and Partnership:

Collaboration with local stakeholders, including suppliers, government entities, and industry associations, can provide invaluable insights and support in navigating the complexities of global manufacturing. Foster mutually beneficial partnerships based on trust, transparency, and shared goals to leverage local expertise, mitigate risks, and drive continuous improvement initiatives.

Technology Integration:

Embrace advanced technologies such as IoT, AI, and data analytics to enhance visibility, efficiency, and agility within global manufacturing operations. Integrated digital platforms enable real-time monitoring of production processes, predictive maintenance, inventory optimization, and performance analytics, empowering businesses to make informed decisions and proactively address challenges.

Continuous Evaluation and Adaptation:

Maintaining a global manufacturing footprint requires ongoing evaluation and adaptation to changing market dynamics, regulatory requirements, and technological advancements. Regular performance assessments, benchmarking against industry peers, and soliciting feedback from stakeholders enable businesses to identify areas for improvement, optimize processes, and stay ahead of the curve.

#GlobalManufacturing #SupplyChainManagement #CostOptimization #QualityAssurance #RiskManagement #SiteSelection #TechnologyIntegration #BusinessStrategy #SupplyChainOptimization #ManufacturingExcellence

Read more views