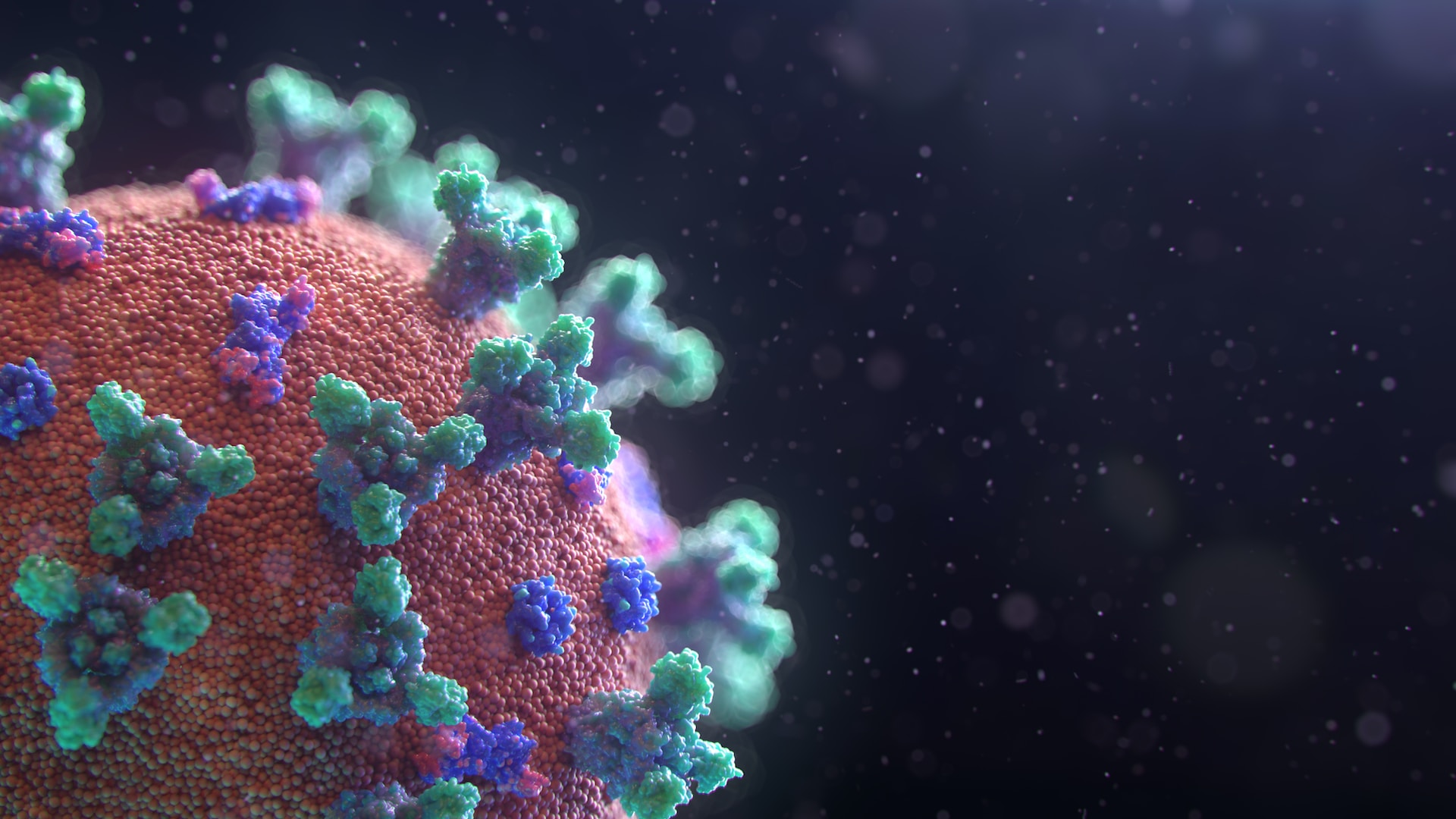

The Covid-19 pandemic has significantly affected the US manufacturing industry, resulting in supply chain disruptions, facility closures, and changes in customer demand. It has, however, also given firms chances to adapt and develop. The financial crisis has sped up the adoption of cutting-edge technology, sparked initiatives to reshoring and nearshoring, and increased government assistance. It is likely that the US manufacturing sector will emerge from the recovery stronger, more resilient, and better equipped to confront new challenges.

Supply Chain Disruptions

In attempt to stop the spread of the virus, countries have closed their borders and implemented lockdown procedures, which has severely impacted global supply networks. As a result, sourcing raw materials, components, and finished items from foreign vendors has proven difficult for US businesses. As an illustration, automakers including Ford, General Motors, and Tesla were had to temporarily cease production as a result of a shortage of parts from foreign suppliers.

Factory Closures and Workforce Challenges

Numerous US firms were briefly shut down to stop the virus's spread, which reduced production output. A dramatic drop in production capacity was caused by the closures, and businesses like Boeing and Airbus suspended their manufacturing activities. Additionally, social isolation policies and worker disease have affected output and productivity in enterprises that remained open.

Changing Consumer Demand

Consumer demand has changed as a result of the epidemic, with some industries seeing an increase while others have seen a fall. Consider the surge in demand for personal protective equipment (PPE), such as gloves and face masks, which forced manufacturers like 3M and Honeywell to increase output. On the other side, because of travel restrictions and economic uncertainties, demand for products in the automotive and aircraft industries fell significantly.

Reshoring and Nearshoring Opportunities

Many US manufacturers are considering reshoring or nearshoring their businesses as a result of the pandemic's exposure of the weaknesses in global supply chains. Manufacturers like Apple and General Electric have relocated part of their operations back to the US or to regions closer to their customers, like Mexico. With this tendency, the reliance on foreign suppliers will be lessened, and the dangers brought on by interruptions in the global supply chain will be lessened.

Technological Advancements and Automation

The use of technology and automation has increased among US manufacturers as a solution to the labor crisis and to maintain production levels. Artificial intelligence (AI), robotics, and the Internet of Things (IoT) technologies have all seen an increase in usage as a result of the pandemic. To sustain efficiency while following social distance rules, organizations like Amazon and FedEx, for instance, have increased their usage of robotics and automation in their warehouses.

Government Support and Stimulus Measures

The government has put in place a number of assistance and stimulus measures to help lessen the pandemic's economic impact on the US manufacturing sector. Businesses were given financial support under the Coronavirus Aid, Relief, and Economic Security (CARES) Act in the form of tax breaks and forgiven loans. These actions have assisted manufacturers in retaining staff, maintaining operations, and making investments in cutting-edge technology.

Related Information