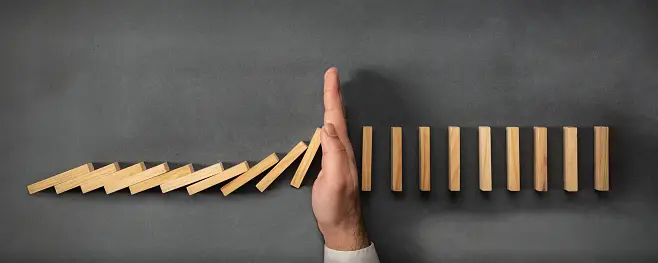

Developing a risk management plan is essential for businesses engaged in international operations to safeguard supply chain resilience and ensure business continuity. By understanding supply chain risks, developing tailored risk management strategies, fostering collaboration and communication, and continuously monitoring and improving risk management practices, businesses can mitigate the impact of disruptions and thrive in the competitive landscape of global trade.

In the interconnected world of global trade, supply chain disruptions can have far-reaching consequences, impacting production schedules, disrupting operations, and jeopardizing business continuity. Developing a comprehensive risk management plan is essential for businesses engaged in international operations to identify, assess, and mitigate risks across the supply chain effectively. Here, we explore strategies for developing a risk management plan tailored to the challenges of international supply chains.

Understanding Supply Chain Risks

- Geopolitical Risks:

Geopolitical tensions, trade disputes, and regulatory changes can disrupt international supply chains, leading to delays, tariffs, and market access barriers. Monitor geopolitical developments, assess country risks, and diversify sourcing strategies to mitigate geopolitical risks.

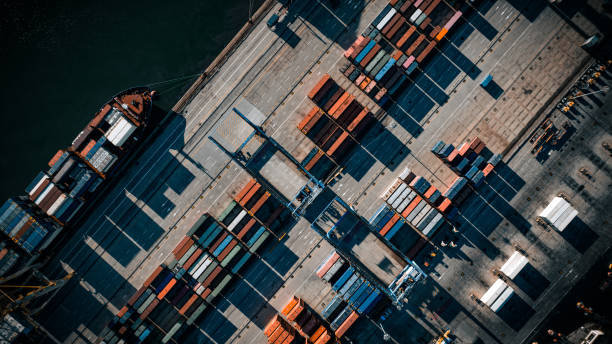

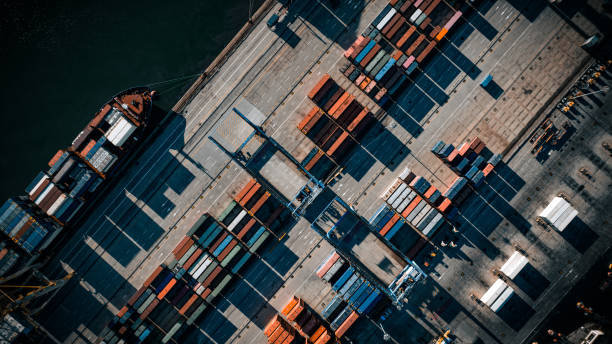

- Logistical Risks:

Logistical challenges such as transportation delays, port congestion, and inventory shortages can disrupt supply chain operations. Develop contingency plans, establish alternative transportation routes, and maintain safety stock levels to mitigate logistical risks and ensure continuity of operations.

- Financial Risks:

Financial risks such as currency fluctuations, payment defaults, and credit risks can impact cash flow and profitability. Implement hedging strategies, secure trade finance facilities, and conduct due diligence on financial counterparties to manage financial risks effectively.

- Operational Risks:

Operational risks such as supplier disruptions, quality issues, and production failures can disrupt supply chain operations. Establish supplier performance metrics, conduct supplier audits, and implement quality control measures to mitigate operational risks and ensure product integrity.

Strategies for Developing a Risk Management Plan

- Risk Identification and Assessment:

Conduct a comprehensive risk assessment to identify potential risks across the supply chain. Analyze historical data, conduct scenario planning, and engage with stakeholders to assess the likelihood and impact of identified risks on business operations.

- Risk Mitigation Strategies:

Develop risk mitigation strategies tailored to the specific characteristics of identified risks. Implement risk controls, establish contingency plans, and develop alternative sourcing strategies to reduce the likelihood and severity of supply chain disruptions.

- Collaboration and Communication:

Foster collaboration and communication with supply chain partners, stakeholders, and regulatory authorities to enhance risk visibility and coordination. Establish clear communication channels, share risk information, and collaborate on risk management initiatives to strengthen supply chain resilience.

- Continuous Monitoring and Improvement:

Continuously monitor and review the effectiveness of risk management measures to identify emerging risks and opportunities for improvement. Conduct regular risk assessments, track key performance indicators, and adapt risk management strategies to evolving business conditions.

#RiskManagement #SupplyChainResilience #BusinessContinuity #InternationalOperations #SupplyChainRisk #GeopoliticalRisk #LogisticalChallenges #OperationalRisk #BusinessStrategy #GlobalTrade

Read more views